Comparing CNC IGBT Module Inverter Cutters: Which Reigns Supreme?

May. 17, 2024

If you're in the market for a CNC IGBT module inverter cutter, you may be feeling overwhelmed by the plethora of options available. To help you make an informed decision, we've compared two popular models to see which one reigns supreme.

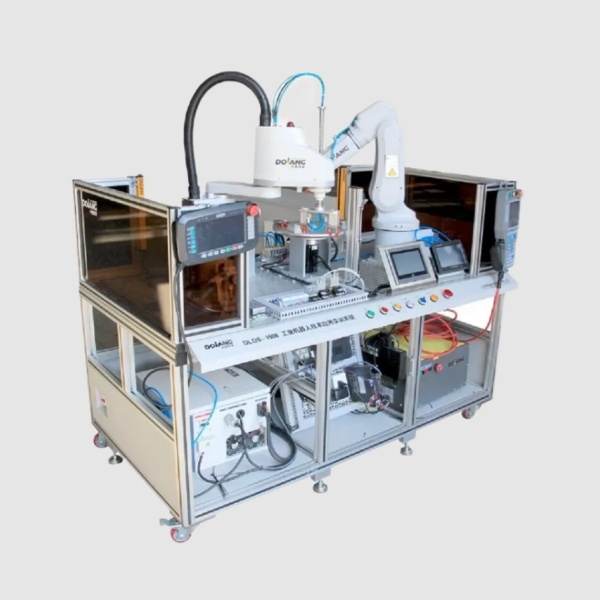

CNC IGBT module inverter cutters are essential tools for precision cutting in various industries, such as manufacturing, automotive, and aerospace. These cutters use insulated-gate bipolar transistor (IGBT) technology to provide high efficiency and reliability in cutting various materials.

Comparing Two Popular Models: .

1. Model A: .

- Offers a cutting speed of 100 meters per minute.

- Features a maximum cutting depth of 200mm.

- Equipped with advanced cooling technology for extended operational hours.

- Comes with a user-friendly interface for easy operation.

2. Model B: .

- Boasts a cutting speed of 120 meters per minute.

- Provides a maximum cutting depth of 250mm.

Additional reading:Is 1500W high power fiber laser cutting machine truly a game changer for industrial manufacturing?

Best Tips for Choosing Sheet Metal Laser Cutting Machine – Which Features Matter Most?

Revolutionizing Manufacturing: Super Large Format Laser

Everything You Need To Know To Find The Best High Power Fiber Laser Cutting Machine 1500W

What To Expect After Q Switched Laser?

Ultimate Guide to 8000W Sheet Metal Laser Cutting

How do I select a high power laser cutting machine?

- Utilizes state-of-the-art automatic tool changing system for increased efficiency.

- Includes real-time monitoring and alarm system for enhanced safety.

Judging by the specifications, it's clear that Model B outperforms Model A in terms of cutting speed, depth, and advanced features. However, the decision ultimately comes down to your specific needs and budget constraints.

Which Reigns Supreme?

In a head-to-head comparison, it's evident that Model B stands out as the superior choice for those seeking high-performance and advanced features. With its faster cutting speed, greater cutting depth, and innovative tool changing system, Model B offers a more efficient and productive cutting experience.

Dialogue-style Content:

Customer: "I'm torn between Model A and Model B. Which one would you recommend?".

Supplier: "Based on your cutting requirements and budget, I would suggest going with Model B. It offers superior performance and advanced features for a more efficient cutting process.".

Closing:

In conclusion, when comparing CNC IGBT module inverter cutters, it's important to consider factors such as cutting speed, depth, and additional features to determine which model best suits your needs. While both models have their own strengths, Model B emerges as the top contender for its high performance and advanced capabilities. If you're interested in learning more about CNC IGBT module inverter cutters, feel free to contact us for expert advice and guidance on choosing the right supplier for your cutting needs.

If you want to learn more, please visit our website CNC IGBT Module Inverter cutter, air compressor for plasma cutter, best plasma cutter.

Additional reading:When to Use radiation protection solutions?

Choosing the Right Radiation Shielding Materials

How thick can a sheet be laser cut?

What should I know before buying a laser cutter?

Becoming Eco-Friendly: Are Plastic Cutting Machines Harmful?

Ultimate Guide: Choosing Best Sheet Metal Laser Cutting Machine

Radiation detectors for the civil nuclear sector

104

0

0

Related Articles

-

31

0

0

-

32

0

0

-

19

0

0

-

23

0

0

-

23

0

0

-

25

0

0

-

22

0

0

-

27

0

0

Comments

All Comments (0)