What is a waste heat recovery boiler and how does it work?

In industrial processes, a significant amount of heat is generated and often wasted, resulting in lost energy and increased environmental impact.

However, with the advent of waste heat recovery boilers, it is now possible to capture and utilize this otherwise wasted heat. In this article, we will explore what a waste heat recovery boiler is and how it works to maximize energy efficiency and sustainability.

Understanding Waste Heat Recovery Boilers:

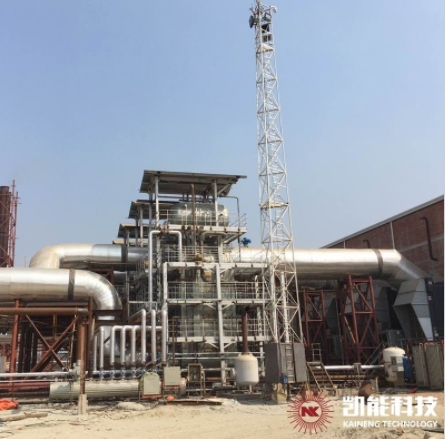

A waste heat recovery boiler is a specialized type of boiler that is designed to capture and utilize the excess heat generated from various industrial processes. These processes can include exhaust gases from furnaces, ovens, engines, turbines, and other equipment. Rather than letting this heat dissipate into the atmosphere, waste heat recovery boilers intercept it, extract its thermal energy, and convert it into useful heat or electricity.

Working Principle:

The working principle of a waste heat recovery boiler revolves around the concept of heat transfer and heat exchange. The boiler operates by recovering heat from the hot gases or exhaust streams, which typically have temperatures ranging from a few hundred to several thousand degrees Celsius.

Heat Recovery:

The first step is to identify potential sources of waste heat within an industrial process. The waste heat recovery boiler is then strategically positioned in the path of these hot gases or exhaust streams. The heat exchanger within the boiler absorbs the thermal energy from the hot gases, resulting in a temperature reduction of the gases.

Heat Transfer:

Within the waste heat recovery boiler, there are tubes or coils that facilitate the transfer of heat from the hot gases to the water or thermal fluid circulating through the boiler. These tubes or coils are often made of high-quality materials that can withstand high temperatures and resist corrosion.

Steam or Power Generation:

As the heat is transferred from the hot gases to the circulating fluid, the fluid is heated, resulting in the generation of high-pressure steam. This steam can be used for various industrial processes or passed through a steam turbine to generate electricity. In some cases, waste heat recovery boilers can also produce hot water or thermal oil for heating applications.

Benefits of Waste Heat Recovery Boilers:

Waste heat recovery boilers offer numerous advantages to industries, including:

Energy Efficiency: By capturing and utilizing waste heat, these boilers significantly improve energy efficiency and reduce reliance on external energy sources.

Cost Savings: Recovering waste heat translates into reduced energy consumption, resulting in cost savings for industrial operations.

Environmental Impact: Waste heat recovery boilers contribute to sustainability efforts by lowering greenhouse gas emissions and reducing the overall carbon footprint.

Process Optimization: By utilizing waste heat, industrial processes can operate at higher temperatures or achieve better thermal efficiency, leading to improved productivity and performance.

Conclusion:

Waste heat recovery boilers play a crucial role in optimizing energy utilization and reducing environmental impact in various industrial sectors. By effectively harnessing and converting wasted heat into usable energy forms like steam or electricity, these boilers contribute to energy efficiency, cost savings, and sustainable practices. As industries continue to prioritize resource conservation, waste heat recovery boilers are becoming indispensable components of energy management systems, driving us closer to a more sustainable future.

165

0

0

Comments

All Comments (0)