Revolutionized Metal Forming: Spinning Machines Redefining Efficiency?

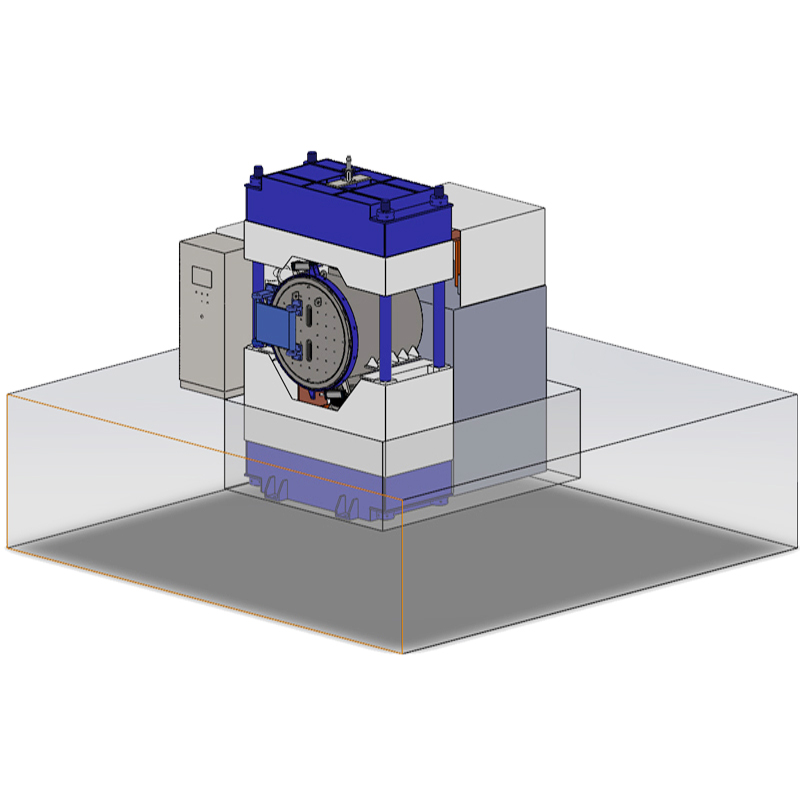

In the ever-evolving world of manufacturing, technological advancements continue to reshape and enhance various processes. One such area that has experienced a revolution is metal forming. Traditionally, metal spinning, a process widely used to create complex, symmetrical shapes, was achieved through manual labor. However, the advent of spinning machines has not only redefined the efficiency of this method, but also unleashed a host of possibilities. In this blog, we delve into the fascinating world of spinning machines, uncovering the ways they have transformed metal forming.

Section 1: The Technological Leap.

Section 2: Unmatched Efficiency.

In an era where efficiency is paramount, spinning machines have delivered exceptional results. These machines can execute multiple spinning operations simultaneously, boosting productivity and minimizing downtime. The automated nature of spinning machines eliminates the need for constant human supervision, leading to reduced labor costs. Additionally, advanced spinning machines come equipped with cutting-edge sensors and real-time monitoring systems, enabling quick detection and correction of any deviations. Such efficiency not only saves time and resources but also ensures consistent high-quality production.

Section 3: Enhanced Accuracy and Precision.

In the competitive manufacturing landscape, precision is of utmost importance. Spinning machines employ cutting-edge computer-aided design (CAD) software, providing designers with unrivaled capabilities to create intricate metal components. The software's simulation feature allows engineers to visualize the spinning process, detecting potential design flaws early on and optimizing it for flawless execution.

Additionally, spinning machines utilize programmable software controllers that ensure accurate execution of spinning operations. Each parameter, from rotational speed to pressure, can be precisely controlled, optimizing the final product's quality. The marriage of technology and craftsmanship in spinning machines has resulted in a level of accuracy and precision that was previously unattainable through purely manual methods.

Additional reading:Boost Efficiency & Precision: Automatic Pouch Filling & Sealing Machine – Answering All Your Product Packaging Needs

Streamline Production with Auto Suction Plate Loader: Boost Efficiency & Eliminate Manual Loading Hassles!

How to Match a Hydraulic Pump to a Motor?

Streamline SMT Inspection Process: Dual-Lane Upscale Conveyor for High-End Quality

EPE Foam Bonding Machine: Enhancing Foam Processing Efficiency

Is it worth buying a new gas boiler?

What are the three types of ram BOP?

Section 4: Versatile Applications.

The flexibility of spinning machines has opened up new avenues across multiple industries. Metal spinning was primarily used for decorative and functional art pieces, but with the advent of spinning machines, it has found applications in various sectors. In aerospace, spinning machines can produce complex parts for engines, propulsion systems, and fuselage components that adhere to stringent quality standards. The automotive industry benefits from spinning machines in the production of exhaust systems, fuel tanks, and wheel rims. Even the medical field has witnessed the advantages of spinning machines in manufacturing precision surgical instruments and prosthetics.

Section 5: The Road Ahead.

The innovations within spinning machine technology demonstrate that this revolution is far from over. Researchers and engineers are actively exploring new ways to enhance the capabilities of these machines. Advancements in materials, such as lightweight alloys and composites, are being incorporated, expanding the range of materials that can be spun. Furthermore, developments in artificial intelligence and machine learning hold the potential to further optimize spinning processes, improving efficiency, accuracy, and productivity.

Conclusion:

The advent of spinning machines has undeniably revolutionized metal forming. By combining the precision of technology with the skill of craftsmanship, these machines have redefined efficiency, accuracy, and versatility in the manufacturing sector. As we continue to witness advancements and innovations, spinning machines are set to play an even more significant role in shaping the future of metal forming, unlocking possibilities that were once unimaginable. With their incredible capabilities, spinning machines have truly transformed the way we manufacture metal components, propelling industries towards a more efficient and productive future.

If you want to learn more, please visit our website alloy spinning machine, steel spinning machine manufacturer, CNC Metal Tube Spinning Machine.

Additional reading:Unlocking the Power of Full Cover Fiber Laser Cutting

What are the advantages of using a 10 Head Multihead Weigher in the purchasing stage?

The Ultimate Guide to Polyurethane Coated Steel Screens

What is the temperature of a vibrating screen bearing?

Unmasking the Power of 03C 109 601 J: A Definitive Guide

Which Olvasztótégely Eladó offers the best price and guarantees?

Which animal feed conditioner offers the best value for its price?

113

0

0

Related Articles

-

145

0

0

-

136

0

0

-

138

0

0

-

154

0

0

-

146

0

0

-

153

0

0

-

174

0

0

-

149

0

0

Comments

All Comments (0)