What is the difference between HFFS and VFFS?

What is the difference between HFFS and VFFS?

HFFS (Horizontal Form-Fill-Seal) and VFFS (Vertical Form-Fill-Seal) are both commonly used packaging methods in the food and pharmaceutical industries. Despite their similar objectives - to form, fill, and seal packages - there are distinct differences between these two packaging techniques.

HFFS is a packaging process where the product is horizontally filled into a pre-formed pouch, followed by sealing the pouch to create a finished package. On the other hand, VFFS involves vertically forming a bag from a roll of film, filling it with the product, and subsequently sealing the bag.

The difference between HFFS and VFFS is primarily attributed to the orientation of the packaging machines and the method of forming the package. The horizontal nature of HFFS machineHFFS machines allows for the filling process to occur at a lower height, making it ideal for delicate or fragile products that may be damaged by the drop height associated with VFFS machines. Additionally, HFFS machines have the advantage of being able to handle a wide range of pouch shapes and sizes, providing flexibility in package design.

Additional reading:Powder Coating Aluminum vs. Anodizing: A Comparative Analysis

How to optimize the efficiency of a prismatic lithium battery production line?

Which tractor is best for hilly terrain?

Electric Scissor Lifts: Elevating Efficiency and Safety

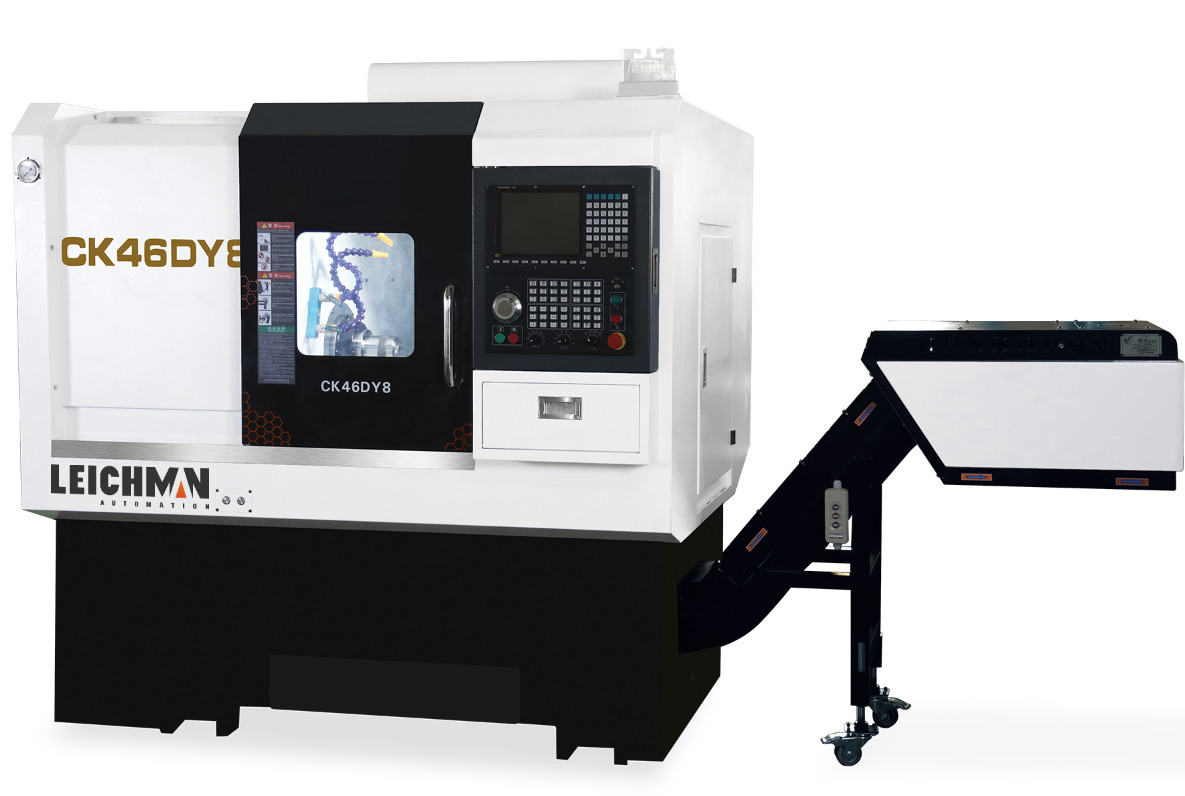

Universal Spline Hobbing Machine: Shaping Precision Gears

Impact Crushers vs. Jaw Crushers: Which Is Right for Your Crushing Needs?

Advantages of Chicken Chips Forming Machine

On the other hand, VFFS machines are known for their high packaging speeds, making them suitable for large-scale production environments. The vertical orientation of VFFS machines allows for efficient and continuous operation, resulting in greater productivity and reduced labor costs. Furthermore, VFFS machines are often equipped with advanced features such as gas flushing for modified atmosphere packaging, ensuring product freshness and extending shelf life.

The selection of the most appropriate packaging method, be it HFFS or VFFS, depends on various factors including product characteristics, desired packaging speed, packaging material, and cost considerations. HFFS is commonly used for packaging products such as snacks, confectionery, and pharmaceuticals, wherein product protection and aesthetics are key considerations. VFFS, on the other hand, finds extensive applications in the packaging of granules, powders, and other dry products.

In conclusion, while HFFS and VFFS share the same objective of forming, filling, and sealing packages, they differ in terms of machine orientation, package formation, and application suitability. The choice between HFFS and VFFS depends on the specific requirements of the product and the packaging process, ultimately impacting factors such as product integrity, efficiency, and cost-effectiveness.

For more information, please visit Flexible Form Fill Seal Packaging Machine, flexible packaging equipment.

Additional reading:Are EVI DC Heat Pumps environmentally friendly?

Which is the Better Transportation Method: Cable Car or Ropeway?

How does a fixed grip chairlift work?

What are the parts of aerial work platform?

How to design an efficient lithium battery module assembly line?

Features of Gloves Counting Machine

Which Super Dump Truck for Sale Is the Ultimate Powerhouse in Construction?

153

0

0

Related Articles

-

149

0

0

-

153

0

0

-

171

0

0

-

161

0

0

-

Maximizing Efficiency: Fuel Consumption of 5-Ton Trucks

Welcome to our blog post where we delve into the world of 5-ton trucks and their fuel consumption.

157

0

0

-

174

0

0

-

165

0

0

-

173

0

0

Comments

All Comments (0)